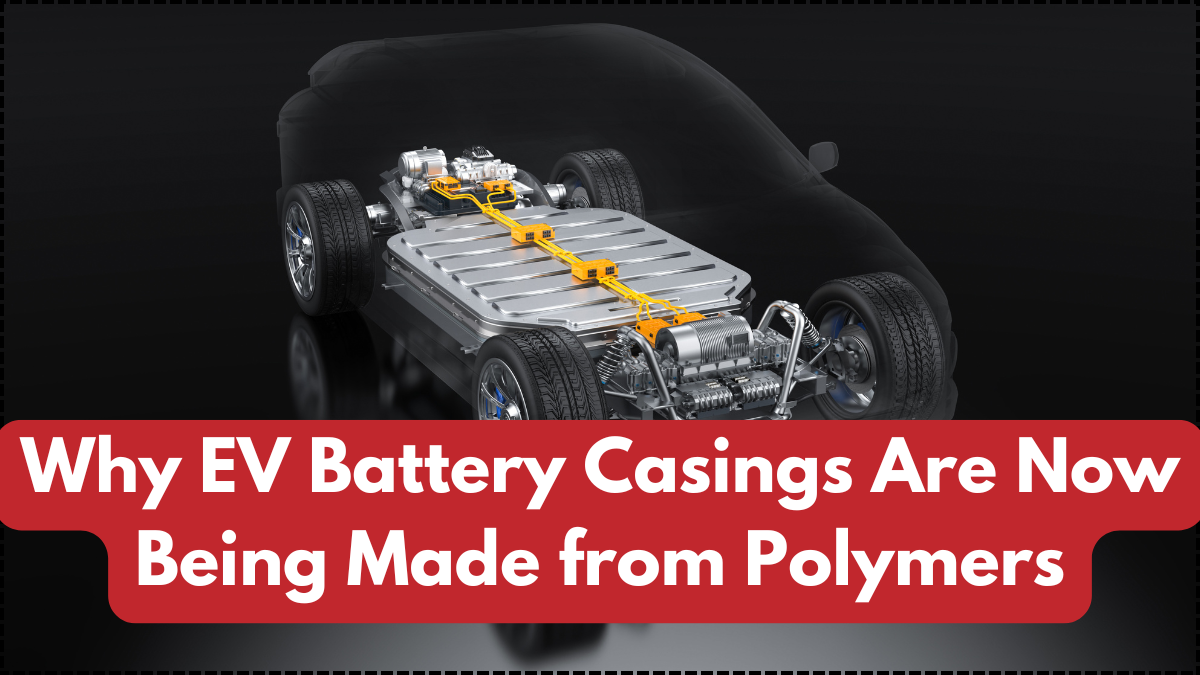

In July 2025, electric vehicles (EVs) continue to dominate the automotive industry, pushing innovation in every component, including battery systems. One of the most transformative developments is the shift toward EV battery casings polymer. Traditionally made from metal, battery enclosures are now being replaced with high-performance polymers due to their exceptional strength-to-weight ratio, chemical resistance, and thermal insulation properties. This shift is not only driving manufacturing efficiency but also enhancing electric vehicle safety standards significantly.

As the EV market grows, ensuring the safety and efficiency of high-voltage battery systems becomes a top priority. Using EV battery casings polymer is proving to be a strategic solution that aligns with regulatory demands and consumer expectations for lightweight, fire-resistant, and sustainable components.

Why Polymers Are Replacing Metal in EV Battery Casings

Metals like aluminum and steel were once the standard for battery enclosures due to their structural integrity. However, in 2025, automakers are realizing that EV battery casings polymer offers advantages that go far beyond traditional materials—especially in the areas of thermal management and crash safety.

Benefits of polymer-based battery casings include:

-

Weight Reduction: Enhances driving range in EVs

-

High Thermal Stability: Crucial for fire prevention and electric vehicle safety

-

Chemical Resistance: Protects battery cells from leakage or exposure

-

Electrical Insulation: Minimizes risk of short circuits or electrocution

-

Cost Efficiency: Easier to mold and manufacture at scale

These polymers are engineered for flame retardancy and structural strength, making them reliable for protecting critical EV systems under extreme conditions.

Key Materials Used in Polymer Battery Casings

Automotive-grade polymers used for EV battery casings polymer are specifically developed to meet rigorous safety standards. Below is a table of common polymer materials and their properties:

| Polymer Material | Properties | Application in EVs |

|---|---|---|

| Polycarbonate (PC) | High impact resistance, electrical insulation | Outer casing for battery enclosures |

| Polyphenylene Sulfide (PPS) | High thermal resistance, chemical durability | Heat shields, internal structural supports |

| Nylon 6/6 | Lightweight, strong, heat resistant | Cell separation, connector housing |

| Polypropylene (PP) | Chemical resistance, cost-effective | Insulative linings and covers |

| PEEK (Polyetheretherketone) | Extreme strength and heat endurance | High-performance EV battery modules |

These polymers ensure maximum electric vehicle safety while optimizing vehicle efficiency and manufacturability.

Enhancing Safety with Polymer Battery Casings

With more powerful battery packs being installed in today’s EVs, fire prevention and thermal control are paramount. This is where EV battery casings polymer excels. Unlike metal, polymers don’t conduct electricity, which means there’s less risk of thermal runaway incidents. They also act as effective flame barriers in case of battery malfunction, adding another layer of electric vehicle safety.

Moreover, polymers help absorb impact in the event of a crash, preventing internal battery damage and reducing the risk of fires. Their ability to be custom molded allows engineers to design reinforced zones around sensitive areas, which is harder to achieve with rigid metals.

Sustainability and Future Outlook

As of July 2025, sustainability is just as important as safety and performance. Many manufacturers are now turning to recyclable or bio-based polymers to build EV battery casings polymer, reducing the environmental impact of EV production.

These developments are paving the way for:

-

Lower carbon emissions during manufacturing

-

Easier end-of-life recycling of battery systems

-

Reduced dependence on mined metals

-

Higher compliance with global green policies

In combination with advances in battery chemistry and vehicle design, polymer-based enclosures are a critical piece in the evolution of safer, cleaner EVs.

Conclusion

The rise of EV battery casings polymer signals a major leap forward in battery engineering and electric vehicle safety. These high-performance plastics offer the perfect mix of strength, fire resistance, and weight reduction, making them the new standard in battery enclosure design. As of July 2025, with electric vehicles leading the mobility revolution, polymer battery casings are ensuring that this progress is not only efficient—but also safe and sustainable.

FAQs

What is an EV battery casings polymer?

EV battery casings polymer refers to plastic-based materials used to encase and protect the battery systems in electric vehicles.

How do polymer casings improve electric vehicle safety?

By offering thermal insulation, electrical isolation, and crash impact absorption, EV battery casings polymer plays a vital role in electric vehicle safety.

Are polymer battery casings as strong as metal ones?

Yes, many engineered polymers used in EVs provide equal or greater durability and heat resistance compared to metal, especially under crash conditions.

Are polymer battery casings recyclable?

Many EV battery casings polymer materials are designed to be recyclable or made from bio-based sources, supporting sustainable EV manufacturing.

Click here to know more